How to ensure safe bunkering of drinking water from a supply vessel

All offshore facilities shall be able to receive drinking water from a supply vessel.

Bunkering water is a simple process mechanically, but from a hygienic perspective there are many factors that need to be controlled in order to avoid pollution.

And there are many good reasons for that. Every year, thousands of food and waterborne illness cases are registered in Norway. This leads to between 30 and 70 eruptions, but this is just the tip of the iceberg. Many sick people don’t go to a doctor, because it is usually not necessary. The doctor does not always test the patient either, and the case is therefore not registered. These premises apply both offshore and onshore

Remember this before bunkering:

From a microbiological point of view, it is recommended that bunkering occurs to empty potable water tanks. If you run out of potable water, you may not want to dump the remaining amount of water before trying to bunker again.

In all offshore (closed) drinking water systems, chlorine is added in conjunction with bunkering to kill bacteria, parasites and viruses and thus ensure clean water for consumers.

It may be a good idea to carry out a check of chlorine dosing unit in advance of planned bunkering. This is especially important if it is has been a long time since last bunkering. Chlorine is highly corrosive and can destroy metal and plastic components in the chlorine dosing plant. Make sure the pump starts and stops properly.

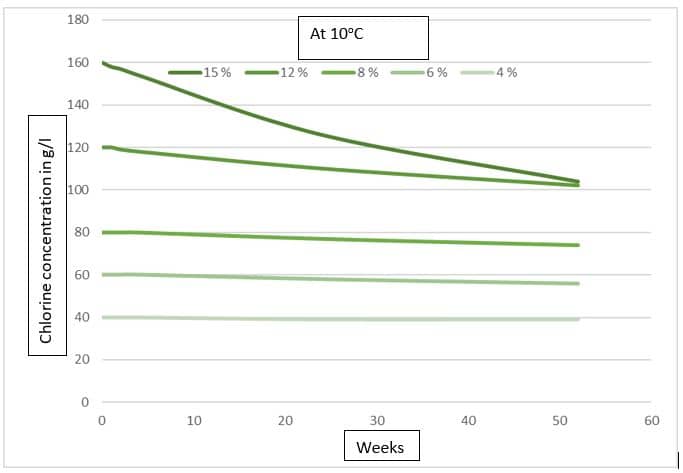

Check the durability of the chlorine solution you intend to use. See the graphs below for the relationship between the chlorine concentration, storage time and storage temperature.

Use a chlorine calculator to find out how much chlorine you should dose. According to the graph above, you should dose a little bit extra. Also note that water from land contains a lot of dissolved organic matter that will bind to chlorine. Therefore, you often have to calculate to dose twice as much chlorine to get the desired residual chlorine after bunkering has ended. In such cases, we say that “the chlorine demand in water is 50 percent”.

The outlet of the tank that is bunkered to must be closed. It should not be possible to bunk drinking water to the tank that supplies the distribution net. The tank must be isolated until it can be verified that the bunkering has been successful.

Note: Check that the valve against the potable water system is closed and that the flush valve to the bunkering station is open.

Remember this during bunkering:

Check with the utility vessel how many tanks they intend to supply potable water from. This is because a sample must be taken from each tank the utility vessel intends to supply water from.

The bunker hose is connected and the system is flushed with full delivery pressure for three minutes. The valve on the flushing tube is throttled if necessary and a sample is taken from the sampling valve. The sample should be analyzed for pH, conductivity, colour number, appearance, smell and taste:

pH

The pH of bunkered water varies little, and it is not common to find deviations here. The pH should be between 6.5 and 9.5.

Conductivity

The conductivity of the water is affected by salt content and is therefore an indication of whether the water may have been contaminated by sea water during transfer from land to the supply vessel, during transport out to the installation or during bunkering. The requirement is that the conductivity should not be changed compared to what it was when the water left the waterworks on land!

Colour Numbers

Colour numbers are not a subjective assessment and should not be confused with the appearance of the water. Colour is measured using a colour meter – a photometer or spectrophotometer. The colour of the water is a measure of how much dissolved organic matter there is in the water. High dissolved organic matter content will provide better growth conditions for bacteria, higher chlorine requirements, greater risk of unwanted chlorine by-products and lower disinfection effect through the UV plant. Water colour varies widely from waterworks to waterworks. Surface water is generally high in colour and water from waterworks in Western Norway is often between 5 and 15. The requirement is that the colour number should be less than 20.

Smell, taste and look

The sensory properties of the water should be considered. It is important that this is taken seriously. The human body is incredibly sensitive, and it is actually possible to taste / smell certain hydrocarbon compounds down to the microgram level.

If the potable water is accepted, the bunkering can begin and the water can be brought down to the storage tank together with the biocide, which is usually the case of chlorine (hypochlorite) in the Norwegian sector. It is important that the chlorine is dosed together with the water. Chlorine dissolves poorly in water and will sink to the bottom of the tank if added afterwards. One will then get an undesirably higher chlorine concentration at the bottom of the tank.

If some of the measured parameters are outside the requirements, it is important to reject the water. By taking the water on board, you violate Section 5 of the Drinking Water Regulations and you risk the utmost consequence of contaminating the system with potentially hazardous substances.

Remember this after bunkering:

The tank should be isolated for 30 minutes before a sample is taken and tested for the level of biocide. When using chlorine, the concentration should be between 0.1 and 0.5 mg / l. If possible, leave the tank in circulation while isolated.

The chlorine content will decrease over time. If there is too little chlorine in the water, more chlorine must be added before a new sample is taken after 30 minutes.

Record all results and observations. This makes it easier the next time you bunker water and can facilitate any future troubleshooting work!